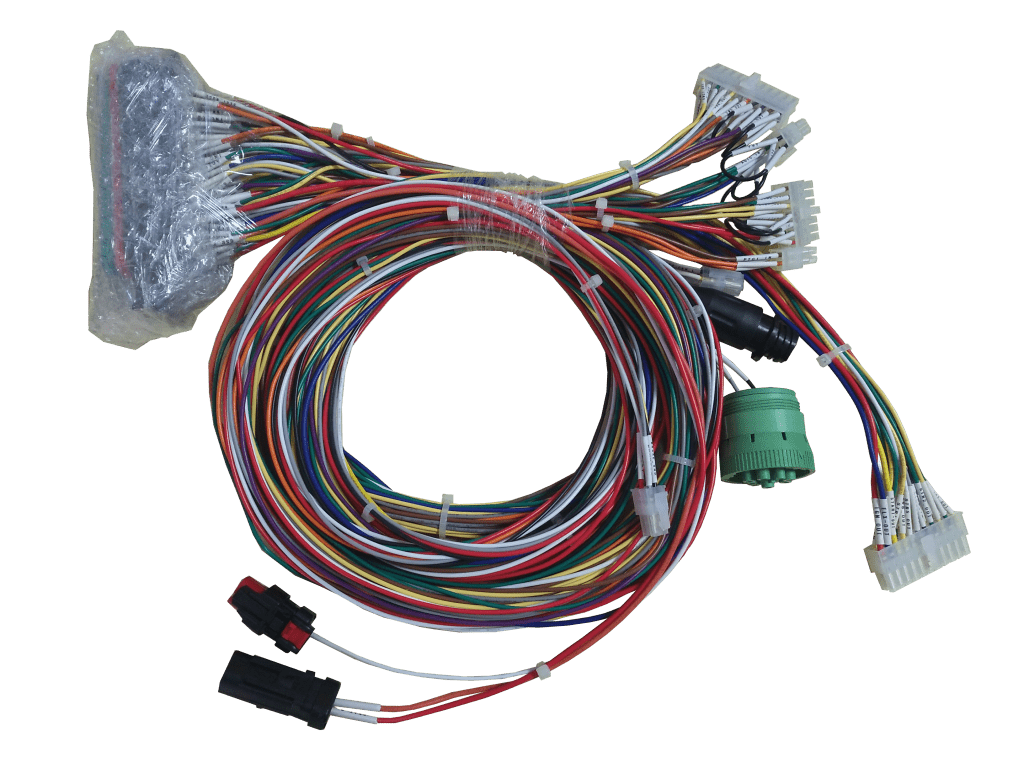

Our Harness Tech supplies a wide range of top-quality wiring harnesses for the robotic industry.

Our technicians customize wire and cable designs to perform at the highest level.

Furthermore, we consider the tension and mechanical stress cables must create within the robotic industry.

This ensures that external factors, like extreme temperatures, do not affect the efficiency of our products.

With over ten years of wiring harness manufacturing experience, we have the right solutions for your robotic cable and wire needs.

We can always help you get the best cable products that fit your needs.

For us to create a robotic wiring harness, you need to provide a detailed drawing including:Manufacturer Part Numbers of the materials (accept alternatives or not) Wiring diagram. Any special requirements, if there are.

Circular and type power connections Custom made with little minimums and quick turnarounds. Free prototyping made by an experienced technical team Stringent quality control and testing on each product Made to customer requirements Proficiency and support in cable harness.

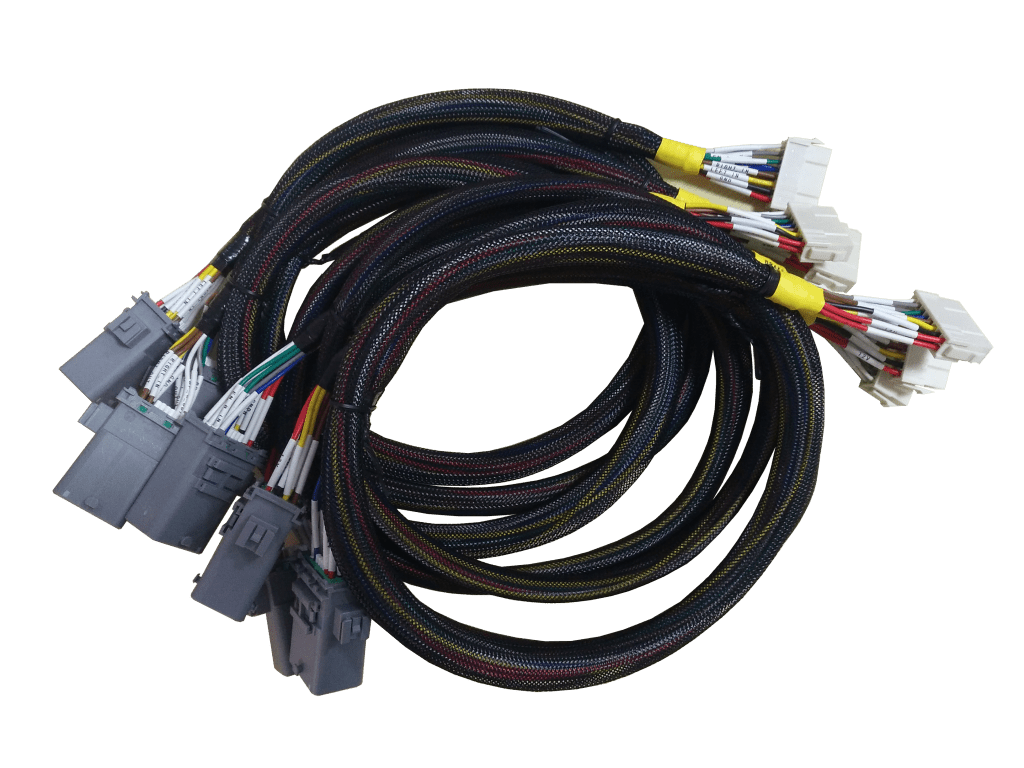

For a cable to tolerate recurring torsional movement, it should have a unique design. That is to say, the transmitters must protect the structure. Additionally, cable jacket components should accommodate significant bending load and radius modifications. We use ‘soft” structural materials that absorb torsional forces to achieve this.

Below are the features of our robotic cables and wires:

We can meet your needs whether you are searching for a prototype or a multi-wiring harness. Apart from the robotic industry, we also serve the automobile, medical, communication, and other industries. We customize, manufacture, and test our products according to international standards.

These are our technical and quality assurance capacities:

| Technical Capacities | Testing and Quality Assurance |

| Strip and crimp AWG50 to AWG12 | Pin assignment |

| Injection overmold capacities | Electrical continuity |

| High flex cables | Insulation tests for high voltage cables |

| Continuous flex cables | Custom test requirements are available on request. |

| Control and instrumentation cables | |

Do you lack documentation? There is no need to worry!

Our experienced technicians are ready to work with anything- from sketches to blueprint samples.

Robotic systems have several sets of wires and cables extending from different components.

To effectively handle them, you need a wiring harness assembly in your robot. That alone makes these products an integral element of the robotic industry.

Our ISO 9001:2015 certification demonstrates our commitment to quality wiring harness services and products.

The current robotic industry demands small and more compact components. Moreover, the wiring harnesses for such devices are challenging to produce manually.

Luckily, Our Harness Tech acknowledges the demand for smaller devices while meeting dense electrical requirements. We have cutting-edge technology and skilled personnel to have your work done.

Besides, our customized flat and round cables manufactured in China are available in all assemblies.

Note that Our Harness Tech wires and cables support up to 150 million flex cycles. Minimize your preventive maintenance expenses by sourcing your robotic wiring harness products from us. Importantly, we deliver customer orders within the shortest time possible!

We pride ourselves on diverse production capacities, verified processes, and skilled professionals. All these enable us to solve the needs of our robotic customers consistently.

More importantly, we make every wire and cable to the client’s specifications. In addition, we allow our customers to check and approve the initial instance of each part before we start bulk production. Apart from that, each piece, assembly, and product undergo complete testing and inspection.

We do this to guarantee the best quality that meets the ISO standards.Our Harness Tech has the right technology and skills to manufacture quality wiring harness products.

We will supply you with the best-connected products per your project’s requirements. Even in extreme conditions, our cables and wires function effectively. Please send us your wiring harness requirements today.

We are confident you will get the value for your money! Remember, we handle all orders regardless of the time frame.

Our experts can help you customize, source, and assemble complicated Dresspack products.

Our Harness Tech manufactures dress pack assemblies from a quantity of 100 m.

Besides, as the leading supplier of wiring harness products, we have established our brand in the global market. We guarantee high flexibility and speed to our customers. Contact us today for all your special cable orders.

At Our Harness Tech, we do not settle for less and go beyond the norm to meet our clients’ expectations and requirements. From the first product development stage and prototyping to final bulk production, Our Harness Tech is your number one partner.

Remember, you can use our cable and wire products in industrial, warehouse, medical, and humanoid robotic applications.

Contact us today for all your robotic cable needs.

The use of wiring harnesses reduces the wear and tear on cables, wires, and other electrical components. This can lead to a lower need for maintenance costs as well as increased longevity in robotic systems.

With Our Harness’s skilled workers, you can get the best of both worlds. We offer a one-stop shop for all your robotic needs–not only will we help with wiring and cabling harnesses that are just right for your system, but also provide services to ensure quality production efficiency from start to finish!