With over ten years of experience as a leading custom wiring harness manufacturer,

we have been providing excellent custom products and services to our clients.

We are a fast customization wiring harness factory.

After ten years of powering subjects, we’ve fine-tuned the custom wiring loom services and are committed to helping you simplify your workflow, launch faster, and make your business boom.

We provide various prototyping and manufacturing services to support our customers’ individual needs. Fully-automated production equipment has largely shortened production time.

According to your drawing or spec sheet.

UL, ISO9001, 14001, 18001, IATF16949 System Management.

The better source of MOLEX, JST, TE, DUPONG, HIROSE.

Skillful foreign trade staff to deal with your cases to save your energy.

All the terminal crimping passed Cross-section analysis.

100% Tested online and IEC spot testing at OQC Dept.

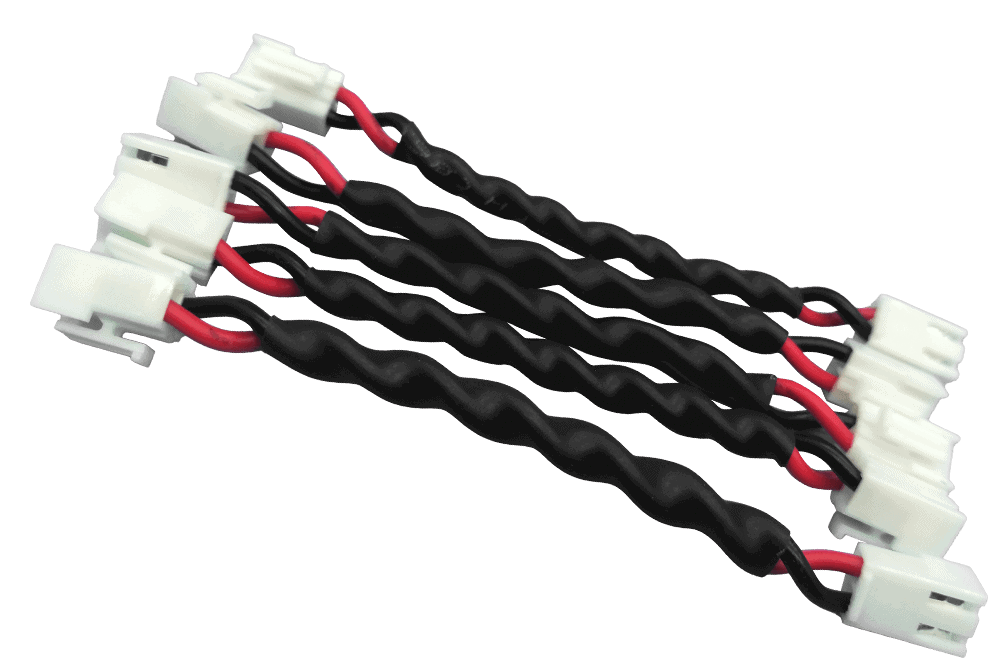

A wire is a strand of material, conductive material, that conducts electricity, such as aluminum or copper.

Cables are usually braided or twisted strands of conductor that’s then sheathed in protective material.

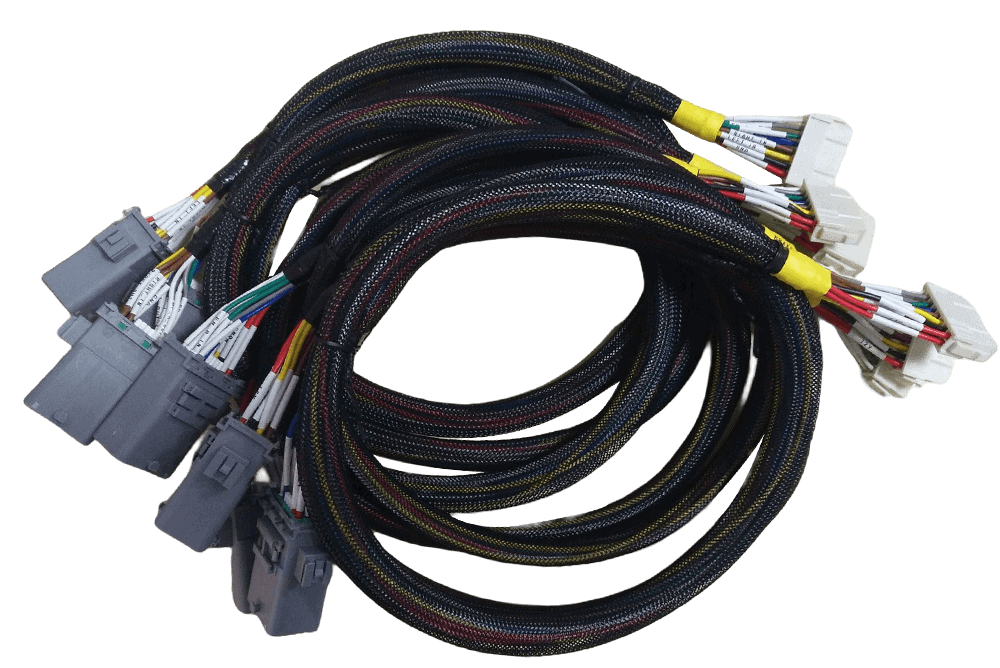

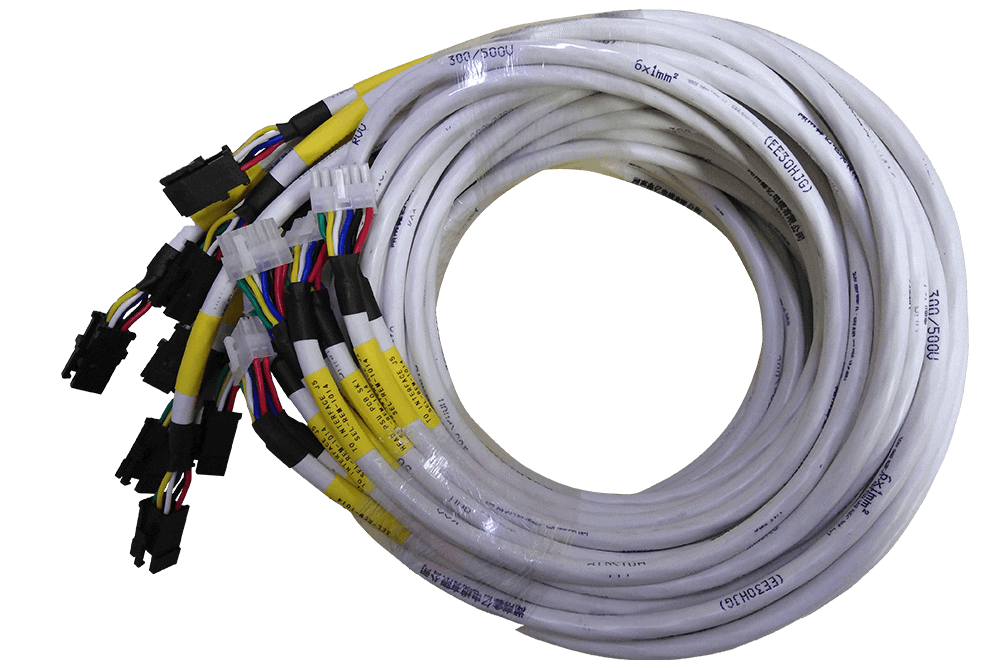

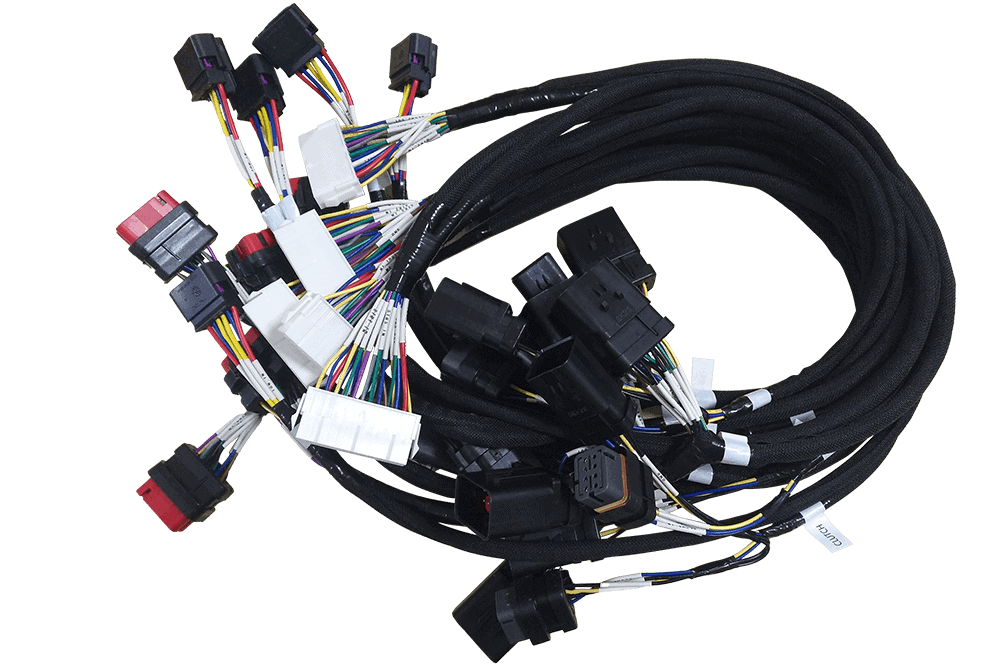

A wire harness is a collection of cables or wires with protective covers, sheath material like thermoplastic. In another word, a wire harness is a simple exterior sheath that covers some wires or cables. Wire harnesses offer a low-cost solution, for they provide a bundle of cables and wires with some degree of protection while keeping them organized for ease of installation and future service.

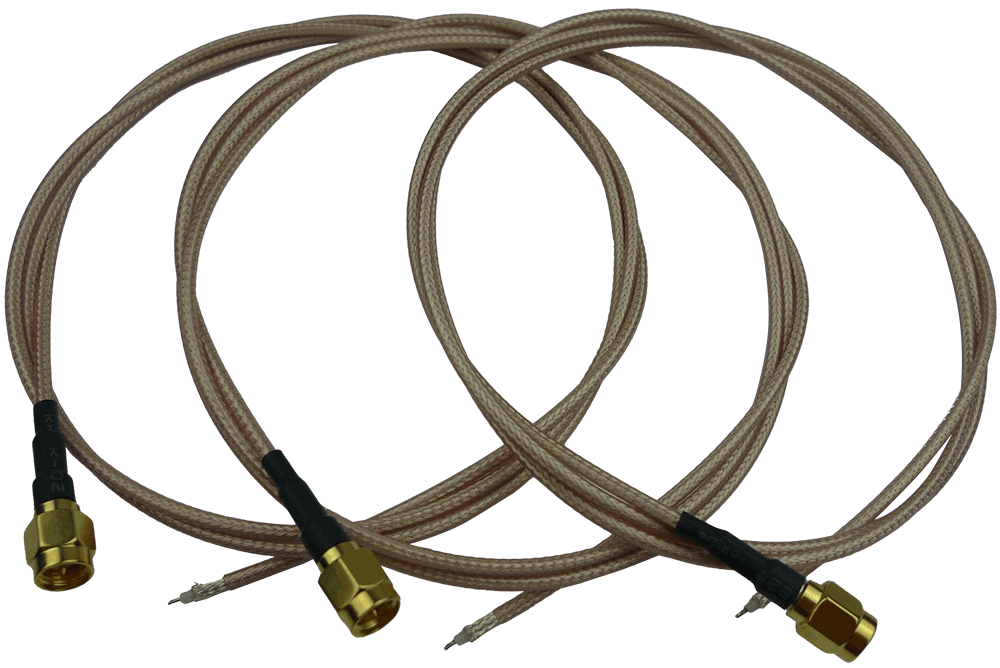

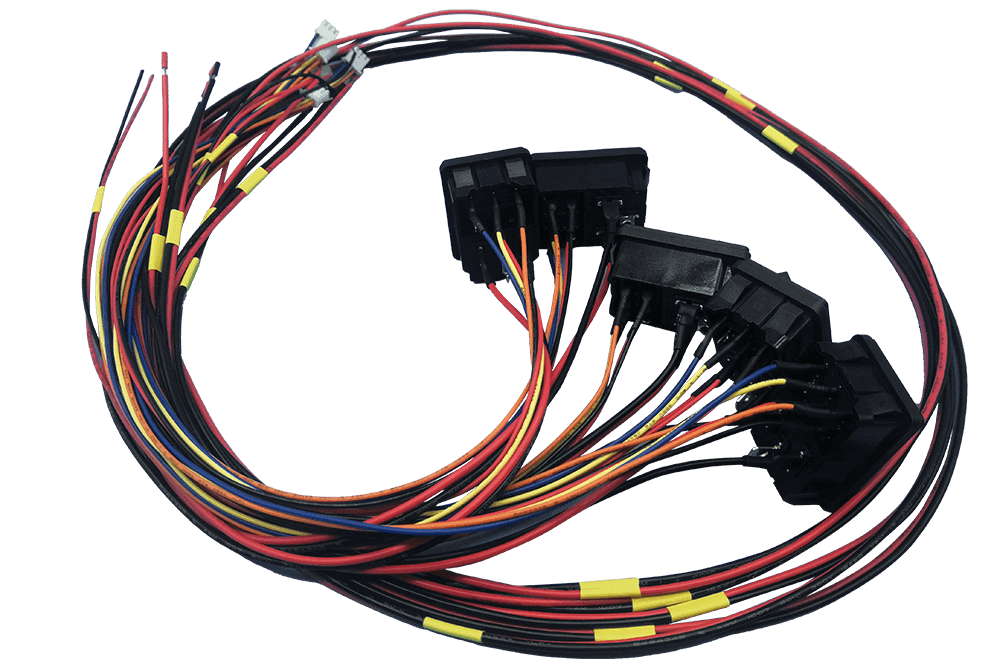

When it comes to a brief explanation of cable assembly, it provides much more robust protection by keeping components snug within a rugged outer sheath. For this reason, cable assemblies can shield the interior wires and cables from heat, extreme heat, friction, moisture, abrasion, compression, and other hazards.

But people often take electrical wiring harness, loom, cable assembly, wiring assembly, coax cable, RF cable, injection-molded cable assembly, fiber optic cable, cable harness as one thing.

Heavy duty wiring harnesses are used for a wide range of applications to power large, heavy machinery. They come in various sizes and types depending on the current, voltage, frequency, or temperature that they will be exposed to.

Cable ties are small plastic strips that can be used to bundle or secure wires, cables, and other cords.

A car’s electrical system needs a power source to function properly. A wire harness provides the necessary connection between a different power source such as batteries and alternators in order for them to be able to work together without interference from one another.

Wire harnesses are a crucial part of electronics, and the size or thickness can have significant consequences. A wire with too low an electrical requirement is prone to overheating due to poor insulation while likewise one that has requirements that exceed its capacity may also overheat but for different reasons. Electrical conductivity is a measure of the ability to transmit an electrical current. A wire harness should have a low impedance in order to reduce power loss due to resistance and crosstalk, but not so much that it causes excessive attenuation or signal distortion.

It has a simple push-button design that allows you to turn the light on and off with ease, even while wearing gloves or in low visibility situations like nighttime driving. The connector also works well as an emergency backup source of power when your vehicle battery dies!

A wire harness assembly process is responsible for linking the electrical components of a vehicle to one another. The final product should be able to withstand rigorous testing and will need an impeccable design in order to function properly. So, finish the installation by professionals or under the guidance of professionals. Making wire harnesses is no easy task, but at least we’ve got some simple wiring for you!

There is strain on wiring system from being pulled, bent, or simply flexed over time, so wire harnesses need a strain relief to keep the wires from becoming loose or breaking.

The wiring harness – wishbone style is the most efficient way to wire your car. In general, it’s less of a hassle and easier on both you and your vehicle when you use this type of wiring as opposed to standard two-wire arrangements in cars made before the 1990s or so.

Wire harnesses are called many different names, including electrical wiring harnesses, looms, cable assemblies, wiring assemblies, cable harnesses, coax cables, RF cables, injection-molded cable assemblies, fiber optic cables, and many times are simply called harnesses. They are used in a variety of applications from airplane engines to commercial and residential electrical wiring.